Darrell Schmitt checks under an old Fillmore County bridge that will be replaced this summer. (Photo by John Weiss)

The Bridges of Fillmore County

Inspection team ensures bridges are safe

SPRING VALLEY — There’s “more than meets the eye” when it comes to bridge safety, a fact that is not lost on Fillmore County and the officials responsible for its bridges.

Why? Because Fillmore County has more bridges than almost every other county in the state – including all its neighboring counties in southeastern Minnesota.

Not surprisingly, bridge safety and inspections are a major concern each spring – and that falls on the shoulders of Engineering Supervisor Darrell Schmitt. Among the many duties he manages from the county’s highway shop in Spring Valley is bridge inspections.

The Inspection Specialists

When I arrived to learn more, two men were talking outside – but I immediately knew who Schmitt was; the hip boots and headlamp were a dead giveaway. What followed was a course in ‘Bridge Inspection 101’, with a few advanced items added.

Before, I sort of thought inspectors would look at the bridge, make sure things are in the right place and that there’s not a lot of rust or cracks. And then on to the next one. It took Schmitt less than a half hour to crush that preconception and flood me with details about how it’s done right.

Schmitt said he’s been with the county 24 years, working highway work in Iowa for 10 years before coming north to Fillmore County. He said he’s usually more of a desk guy now, but come spring, he gets to be outside, and he loves that.

Darrell Schmitt explains the intricacies of how a bridge’s condition is rated. (Photo by John Weiss)

He loves the quiet. He loves bridges. He loves his job. And he’s proud of the job he and the three other inspectors – Jim Thorson, Chris Aasum and Josh Lensing – do.

“We are fortunate we have four inspectors,” he said. “Some counties don’t have any, it’s a hard process to get through. Inspection costs are part of our salaries therefore it’s a huge savings for the county,” he said. Several Counties do not have Certified Bridge Team Leaders and must hire consultants, he said. Single inspections average $600 or more.

All four had to work with senior inspectors as well as take classes to become inspectors. And they have to take more classes later and then tested, he said. “They are trying to get all the inspectors (so) they rate the description all the same.” That would be a consistent theme.

Three Critical Things About Bridge Inspections in Fillmore County.

One: Fillmore County has 466 bridges, second in Minnesota behind St. Louis County (in the state’s Arrowhead Region) which is eight times larger geographically. With so many streams and rivers, a county needs bridges. Townships have 256 bridges, some of them large, and the county inspects them all at no cost, he said.

Two: A bridge is defined as a structure of at least 10 feet over a stream or gully. They include culverts that are becoming a go-to option because they are easier and cheaper to install and last a lot longer.

Three: Some work requires a snooper truck with a long arm to look beneath or even divers to probe deeper than county workers can walk. In that case, the county calls on the Minnesota Department of Transportation (MnDOT).

MnDOT supports area counties with use of its ‘snooper truck’, here being used by Tony Bale and Keith Rosenau to inspect a Wabasha County bridge over West Indian Creek. (Photo by John Weiss)

The age of many area bridges makes close-up work critical, he said.

“A lot of bridges were built in the 1920s to the 1940s. Many of them have masonry abutment. If you don’t look at those structures a lot of times, once those blocks start giving out, it’s like a domino effect, it just goes.” Detecting flaws sooner is better, and cheaper, Schmitt said.

Bridges are also critical for local commerce, he said. “We try to be proactive.”

They inspect 220 to 300 bridges each year. Some need a few hours to inspect, some bigger ones take a day. Older ones might be inspected every year, some are looked at every two years; some culverts annually, others every two years or every four years.

They begin in March and finish in April because snow and ice are gone but weeds aren’t much of a bother so they can see more and it’s easier walking, according to Schmitt. Last year, work was great because weather was great; this year, “we started and it was cold, cold and damp.”

Still, they went out. After heavy rains, they also check bridges that are susceptible to scouring. Regular maintenance crews are out in the roads often and they see the bridges a lot, so any change will stick out, he said.

Speaking of heavy rains, “one thing that’s crazy over the years, it seems like (there are) more frequent and larger” rains and therefore, more soil erosion. Heavy rain last summer wiped out one older bridge – now it’s a culvert.

Learning the Language of Bridge Inspection

Our first stop was County Highway 38 over Bear Creek, northeast of Spring Valley; the creek was high and dirty, much worse than when I did a story there last year and we could easily walk across it. Inspectors will wait for the creek to drop before using probes to check the pilings, he said.

Schmitt used a long metal pole both as a probe and walking stick to safely get over the big riprap.

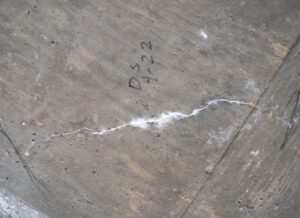

Darrell Schmitt initialed this efflorescence three years ago (Photo by John Weiss)

A spall on a Fillmore County culvert; a spall is a crack or piece of concrete that has broken off. (Photo by John Weiss)

“See that over there?” he said. “That’s spalling.” Spalling? That was a new word for me (also a great one for Scrabble), and it means places where pieces and chunks are missing.

“Over there, see that jagged white line?” Schmitt continued, “That’s efflorescence.” Another new word for me which means a whitish crystalline material formed in a thin crack. Next to it were his initials, indicating he’d identified it in a prior inspection.

“That crack could be in that bridge for 20 or 30 years, it could be in there forever,” he said. “It’s concrete, and concrete is going to crack – it’s just a matter of time. This bridge is really in decent shape.”

He even gives each inspector a card the size of a credit card with gradually wider lines so everyone uses the same measurement.

Overall, “next year when I do it, I might give it to a different inspector so you get different eyes on it,” he said.

Climate Change Affects Bridges, Too

Speaking of changes, “when I first started,” he said, “there was just so much debris all the time, it seemed. In certain areas you go and oh, it’s jammed up again” – and two months later, it was jammed again. But now, he said, “it seems like there is less and less debris.”

Maybe more flooding gradually removed much of the debris or landowners are cleaning up more. He’s not complaining.

If debris is threatening a bridge, they use machines to lift it out instead of risking injury by sending workers into the water. He could see a log jammed against one of the Highway 38 bridge’s pilings but wasn’t too worried about it.

Darrell Schmitt shows where a whitish substance formed in a crack under a bridge. (Photo by John Weiss)

He continued to show me what he looks for when under the bridge. One crucial factor is weathering of steel beams. That was all good there too, just some minor things. The deck sits on bearings, some fixed, some designed to move so the bridge can shift with weather but not too much. They are critical to check.

Perhaps the most fascinating thing was how they test a bridge deck. I imagined a computerized probe. Instead, they have a metal device that drags four short lengths of chain. That’s it. But as they drag it over the deck, the sound it makes will tell their trained ears how good the deck is below. Simple, effective.

A simple device with four chains is dragged over a bridge deck so trained inspectors can tell what the deck is like below the surface. (Photo by John Weiss)

When he was done, he showed me the ‘technological opposite’ of the chain – a complicated computer report of just about every detail of each flaw, spall, efflorescence and other details.

“They take all these conditions, punch in all the numbers and compare it to the local planning index,” he said. “Now you have to rate it. When it’s all done, each gets a number. If it’s 60 or lower, that’s bad.” The bridge he showed me over Bear Creek was well into the 70s, he said.

The federal government has standards all states must meet but each state, including Minnesota, can add more stringent ones, Schmitt said.

Ultimately, they rate culverts, railings, bearings, coating, everything, on a scale of one to four, the lower the number, the better, he said. “If you have it (at) four, that’s a big deal.”

If people are interested in knowing about a bridge, the quickest way is to check if there are ‘load limits’. Limits mean the bridge has some flaws. The lower the limit, the worse the bridge. Once a bridge is posted, the county tries to get it replaced as soon as possible. People can also call the office to find out whether a bridge is looking good, he said.

Culverts Replace Bridges in Many Places

Next we went to see a few newer culverts. One was over what is usually a dry run of Kedron Creek, north of Spring Valley, but it was flowing briskly after a few inches of rain. The former bridge was blown out last summer in a heavy rain; the new one showed a few minor spalls and a small tree against it. Overall, it’s good, he said. It’s on a rather heavily used gravel road.

Then it was on to a bridge, the old style, that will be replaced this year with a culvert. It was built 90 years ago, is too narrow, has no real railings and is generally failing. To take a better look, Schmitt waded into the stream, probed the concrete base with his metal pole and it sounded solid.

Though the bridge itself was failing, he was impressed. “They took their time when they constructed these bridges in the 1920s and 1930s,” he said. “The WPA (Federal Works Progress Administration) did those and they built tanks.”

Fillmore County Engineering Supervisor Darrell Schmitt stands under a county bridge he had inspected in the past. (Photo by John Weiss)

Fillmore County is fortunate to have several local contractors who specialize in such work; the county does none on its own, he said. They will run a pipe around the old one to handle the flow of a stream, tear out the old bridge, put in a new culvert and close it up. Culverts take two to three weeks to put in, a traditional bridge eight to 10 weeks.

A simple replacement with a culvert can now cost maybe $140,000; the high side would be $550,000. Right now, there are 38 bridges eligible for replacement, he said. In his 14 years, he has seen about 75 bridges replaced, he said.

Money comes from the county, the Local Option Sales Tax, townships or the state. “Our county engineer (Ron Gregg) is very aggressive with looking (for) and capturing additional funding that’s available, such as special bridge bonding or federal funds,” Schmitt said. “The key is to get the bridge replacement plans out early and apply. Special award money may take a couple years to receive but at least you have additional monies to work with.”

Safer Bridges to Show for It

With that, my ‘Bridge Inspection 101’ crash course was over.

Takeaways? I was impressed at the complexity of bridge inspections and now feel better when crossing an older bridge. And I was impressed with Schmitt’s dedication and that of his crew.

“We a do a good job here,” he said. “I’ve got good people, great inspectors.”

…………………

Addendum: Minnesota Department of Transportaion (MnDOT) crews are also hard at it. In southeast Minnesota, MnDOT was set to inspect over 1,100 bridges this spring into early summer, including 450 state structures from traditional spans to culverts, as well as 560 city and county structures.

“The inspections are routine to ensure safety and monitor the effects of traffic, weather, and other elements on the structure,” MnDOT reports.

The first ones were in Olmsted County beginning in April. Along the way inspectors use snooper trucks to get to places that are too high or cross areas too hard to go underneath. The trucks have a multi-jointed arm with a basket that holds an inspector.

These snooper trucks were scheduled to inspect 70 locations into May. In June, MnDOT is scheduled to use snoopers to inspect southeast Minnesota bridges over the Mississippi River in Red Wing, Wabasha and Winona.

Visit MnDOT’s Bridges and Structures webpage to learn more about Minnesota bridge inspections. Additional bridge information can be found on its Minnesota Bridge Inventory page.

…………………

Contributor

John Weiss was a full-time reporter for the Rochester Post-Bulletin for 41 years and wrote the Back Roads column for more than 10 years. His passions include hunting, fishing, birding, nature photography, hiking and just kicking around.